Building rebalanced and resilient supply chains

Not only is Asia Pacific’s booming middle class getting larger and wealthier – it is also becoming more demanding.

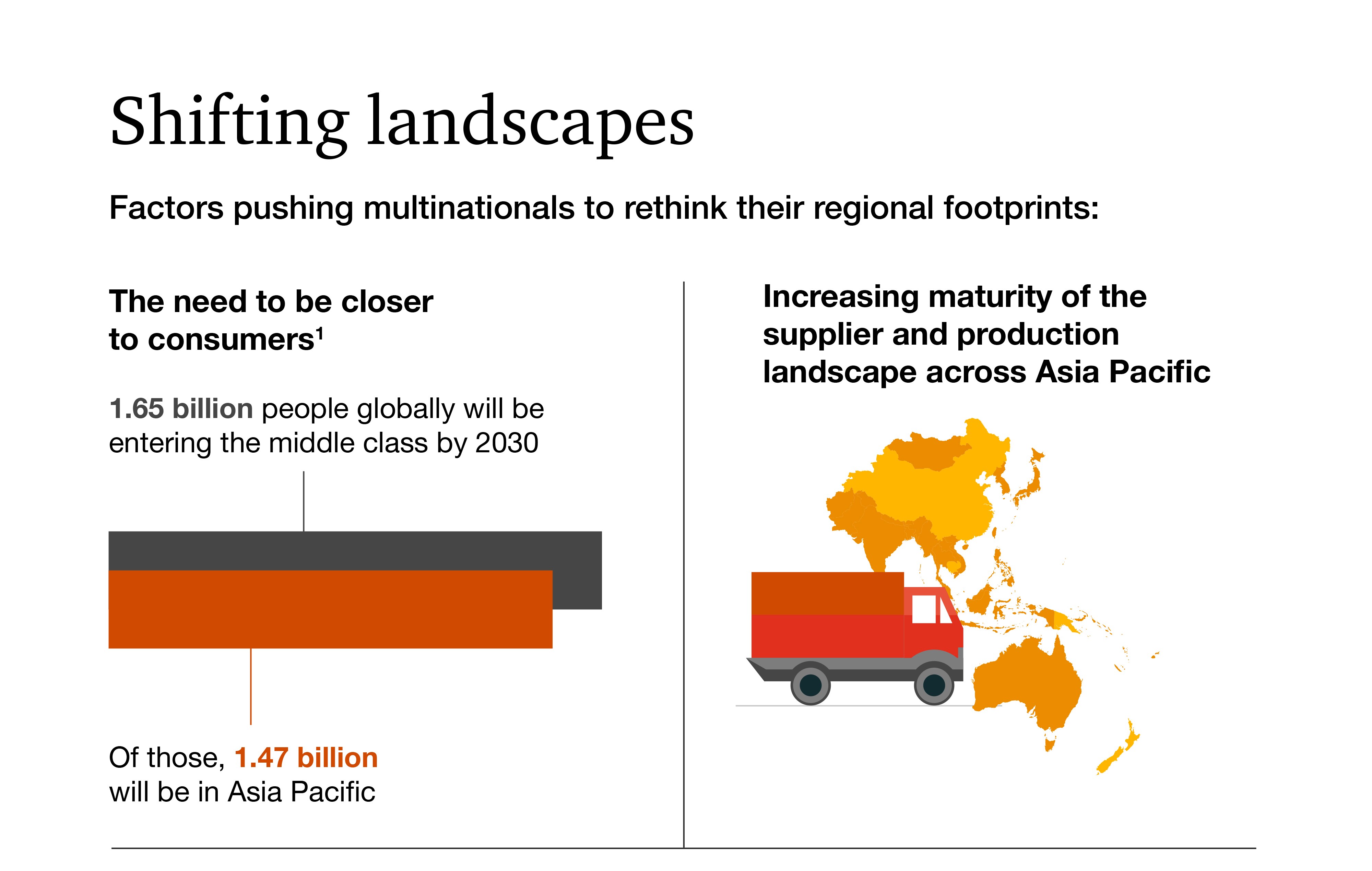

Several urgent matters are solved by companies realigning their supply chain and manufacturing footprint across Asia Pacific. One is the need to stay closer to the region’s growing middle class so as to increase the chances of capturing more of the market and also to respond quickly to their evolving expectations. This isn’t just about saving on transport costs, but instead giving organisations the ability to quickly and confidently identify trends and respond. This means greater relevance leading to enhanced customer experience, sales and loyalty.

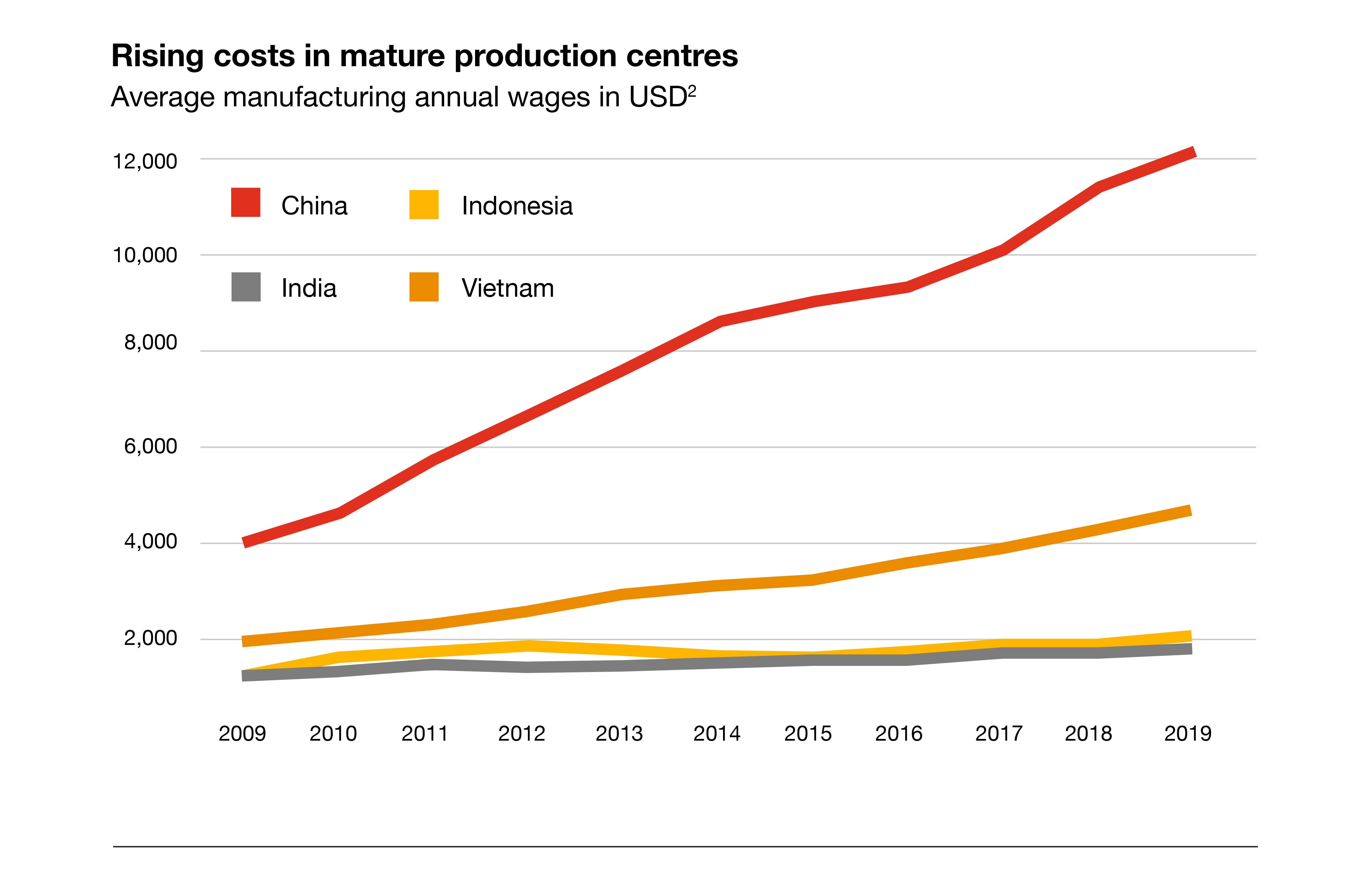

Another key driver is rising costs of labour and tightening regulations in traditional manufacturing locations, and the increasing maturity of suppliers across other parts of Asia Pacific. A rebalanced supplier and manufacturing portfolio creates resilience in supply chains. The COVID-19 pandemic was just the latest warning for business – fragile supply chains simply don’t work in an environment that experiences regular disruptions.

Footprint realignment allows a business to make a powerful strategic shift toward success. It’s a recognition of the fact that market forces always change. Successful organisations are the ones that anticipate that change.

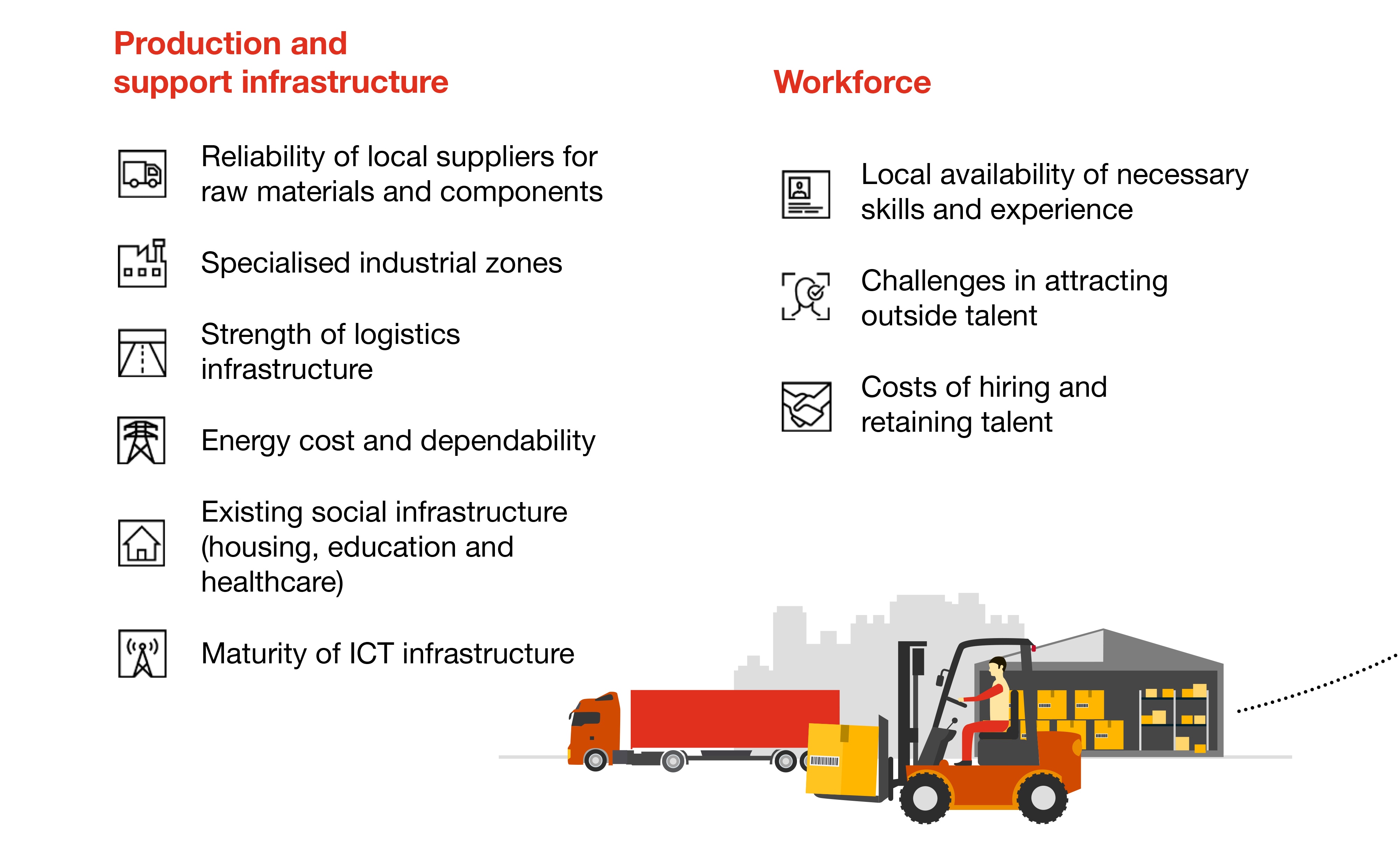

An enormous leap is involved in getting site selection right in a new territory, but it needn’t be a leap of faith.

Local regulations, talent challenges, supplier issues, infrastructure problems, community expectations, cultural misunderstandings and much more can make the process resource intensive, prohibitively expensive, highly risky and time-consuming.

Often the difference between failure and success is process. In this case, best practice involves going beyond due diligence of a shortlist of potential locations, taking in far more detail than the organisation would in a more familiar environment.

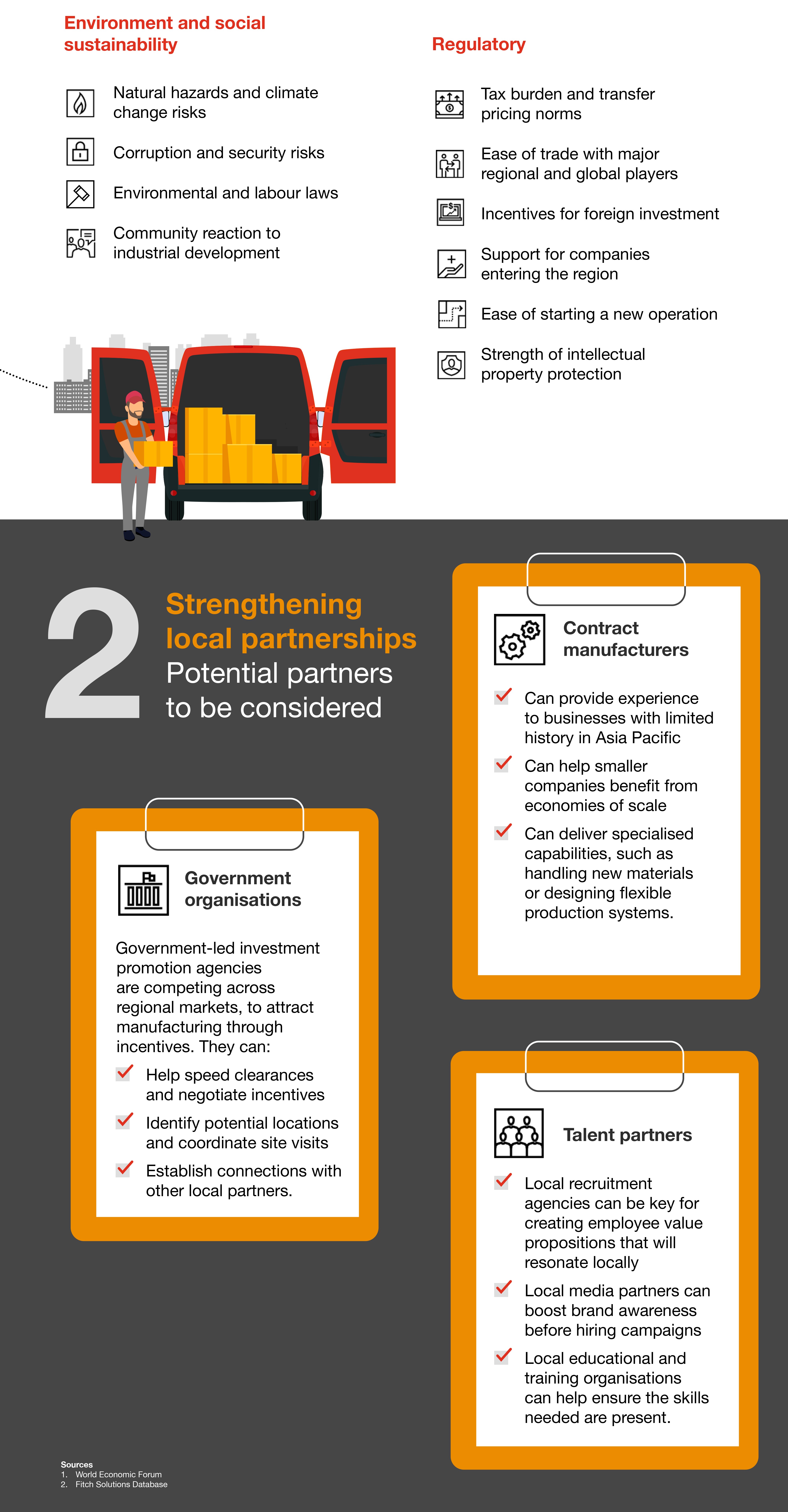

The other vital ingredient in the recipe for success is local partnerships.

Bringing local players on board can mitigate operational risks, build essential relationships with suppliers, talent agencies and government departments, reveal previously unidentified benefits and advantages such as government incentives, and negate customs and trade perils.

The right processes and partnerships will set organisations up for the next generation of success.

Not only is Asia Pacific’s booming middle class getting larger and wealthier – it is also becoming more demanding.

Pressures have long been mounting on businesses to review the globalisation of their supply chains. But the COVID-19 pandemic has presented both a final warning and an opportunity for Asia Pacific to rethink and rebuild.

The unacceptable levels of risk in long and fragile supply chains are not new, nor are they products of the COVID-19 pandemic. However, the experience of the past year has confirmed the time is now to introduce more resilience into supply chains.

The drive towards higher efficiency and lower costs has driven supply chains to be stretched worldwide in recent decades.