How the adoption of blockchain can provide a boost of power and efficiency to the aerospace industry

Data for the life of the aircraft

April 01, 2019

The Problem: What the aerospace industry doesn’t know about its planes is costing it serious money

Today much of the information critical to keeping an aircraft in flight is collected manually, an expensive and time-consuming process. The data showing a plane’s history and condition are spread across up to 40 systems, in the hands of multiple parties who may be competitors reluctant to share data. Mercenary resellers take advantage of airlines and MROs because there is no central clearinghouse of aircraft components. Maintenance is reactive, and it is hard to know which planes are affected when regulators or manufacturers require supersession of a part.

The Solution: A decentralised, immutable consensus-based technology

Blockchain, a digital ledger of transactions taking place in a peer-to-peer network, can record each time a part is installed or removed from an airplane. It can also capture how long the part being replaced was in service and the identity, location and credentials of the technician performing the repair.

It’s like having a digital ‘birth certificate’ for every part, updated every time the plane is serviced or inspected. These birth certificates can be aggregated into a ‘digital twin’ of the aircraft that provides a real-time snapshot of its condition from the moment it exits the assembly line to when it is returned to its lessor or retired from the fleet.

Having a more accurate view of a plane’s configuration and maintenance history could:

- help reduce costs and losses related to downtime and unplanned maintenance,

- boost the value of planes in the secondary market and at the end of leases,

- and improve worker productivity.

Flying with eyes wide open

Blockchain is particularly well suited to tackle aerospace’s unique challenges:

- Maintenance

- Finance

- Workforce

Maintenance

- Improve efficiency. Reduce time spent on routine inspections and maintenance.

- Defeat mercenary parts resellers. Compare the serial number of a part being offered against an indelible, real-time record of ownership, location and utilisation.

- Reinvent aircraft maintenance. Engage in more predictive maintenance. Reduce delays and lost revenue.

- Replace warranties with guarantees. Enable the spread of service arrangements under which a supplier guarantees the supply, repair and overhaul of components and systems.

Finance

- Build value in the secondary market. Extend the maintenance standards of jet engines to the whole aircraft with verifiable maintenance records updated in real time.

- Transform leasing. Make obsolete the need to tear down an aircraft to inventory its parts and assess their condition.

- Improve insurance. Insure individual planes in a way that reflect the risk of each.

Workforce

Blockchain technology, with biometric identity verification, could make it practical to ensure that the identity of every person who interacts with a plane – and the status of their credentials –becomes part of the real-time snapshot of its condition.

In addition to knowing the provenance and history of a part, parties with appropriate permissions could also see in an instant the verified identity and qualifications of the person who installed or serviced it.

Best Practices

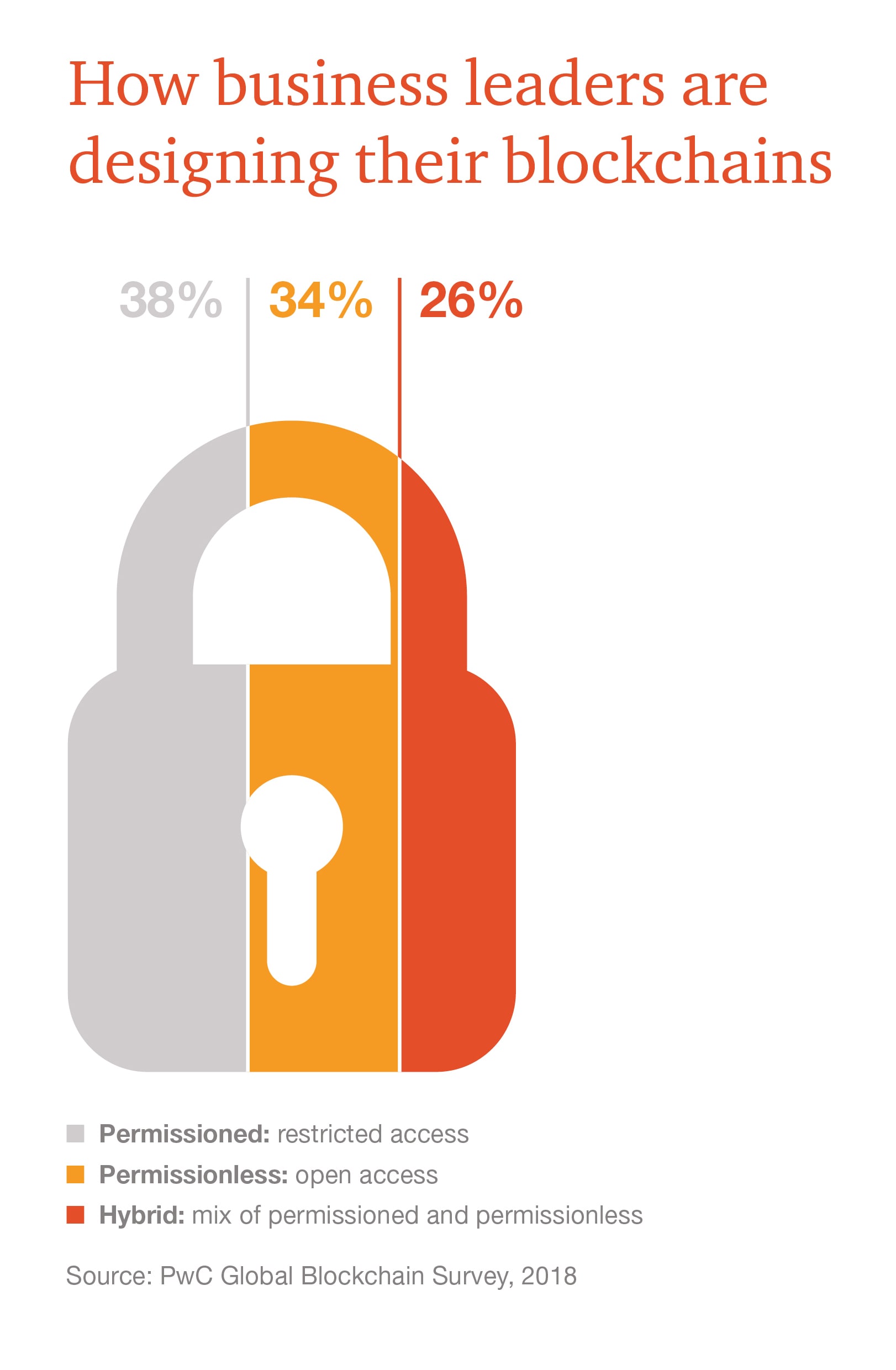

PwC's 2018 Global Blockchain Survey illuminated some of the key steps to focus on to help ensure a successful blockchain project.

- Make the business case. Start with one system or process.

- Build an ecosystem. Bring together stakeholders to establish governance, oversight and audit mechanisms, and rules for participation.

- Design deliberately. Include cybersecurity, compliance, audit and legal specialists.

- Navigate regulatory uncertainty. Develop solutions alongside efforts to build regulatory comfort to show how transparency works.

Approaching liftoff

A picture of each plane’s configuration and maintenance history, accurate up to the second, would make it easier to predict when serious maintenance issues could ground a plane, and to analyse its condition and diagnose potential issues during MRO.

Contact us

Rachel Parker Sealy

Industrial Products Technology Principal, PwC United States

Tel: +1 (314) 206-8183

Scott Thompson

US Aerospace and Defence Leader Partner, Global Mobility Services

Tel: +1 (703) 918 1976