Digital Champions in 2025

April 20, 2020

Successful in connected and autonomous supply chain ecosystems

Learn more about how supply chain leaders -- the Digital Champions -- are benefiting from their investments into supply chain excellence and which capabilities, enablers, and organisational changes are most important to take your supply chain to the next level.

The vision

We’re seeing an important trend towards increasing connectivity in supply chains — both within the company and beyond its walls. The result is a wealth of data that’s now available continuously throughout the supply chain. Ultimately, that’s leading to supply chain ecosystems, where partners have near-real-time and simultaneous access to relevant information — thus, decisions can be optimised and informed by what’s really happening. Data transparency across this ecosystem allows for synchronised demand and supply planning, as well as connected and transparent logistics. And when companies take advantage of artificial intelligence (AI), they can make key activities self-orchestrating. That happens when they are able to define efficiency parameters and embed these in the algorithms that steer decision-making.

This kind of information and connectivity also helps companies to proactively identify and manage supply chain risks — a must in times when supply chain disruptions may have become more the norm than the exception.

Our research shows that most companies have begun this journey and have invested into new supply chain capabilities and organisational models, but that Digital Champions are far ahead.

The benefits

Digital Champions invested 9.1% of their supply chain costs into advanced supply chain capabilities last year and plan to continue even stronger levels of investments. That’s higher than the other companies we surveyed and the results suggest the investments are paying off: In 2019, they saved 6.8% of supply chain costs for the year, well ahead of less advanced companies. They also increased revenues by 7.7%. And they delivered more reliably, enhancing customer satisfaction by achieving higher levels of on-time, in-full (OTIF) delivery, too.

The advantages go far beyond just the numbers. That’s true for all of the companies we surveyed, and especially for the Digital Champions — in addition to enjoying higher profitability and better asset utilisation, they’re also using supply chain to drive improvements across their business. In these current uncertain times, the most important of these may be increasing supply chains’ resilience by understanding risks and responding to them. 28% of Digital Champions say more effective risk management is one of three most important key benefits they are gaining from their investments in advanced supply chain capabilities.

Supply chain transparency and sustainability

Supply chain transparency — understanding exactly what’s happening throughout your supply chain — isn’t a new concept, but advanced capabilities are making an entirely new level of visibility possible. Companies are beginning to use data networks that capture the full range of data and relationships being generated across their entire supply chain from very heterogeneous sources — all the way from raw materials to customers and back.

Although the majority of companies see supply chain transparency as a priority, Digital Champions are significantly farther along the road to achieving end-to-end transparency. They report much greater levels of visibility over product content, supply chain financials on a transaction level and logistics flows in near-real-time. Indeed, nearly half (47%) of Digital Champions implementing planning are already able to use a digital twin of their supply chain. That enhances transparency and dynamic optimisation of the total cost of ownership.

High levels of transparency also help companies respond to increased sustainability requirements across their supply chains, for example by making it possible to track a product’s full chain of custody.

Closed loop and integrated planning

Demand and supply planning is at the heart of supply chain management. The best way to achieve a high level of accuracy and responsiveness in planning is through implementing planning approaches that cover the scope of the end-to-end supply chain including suppliers, carriers and customers. Such approaches cross relevant time horizons so that short-term, mid-term and long-term planning processes don’t happen in silos, but are fully integrated and linked with volume planning and financial planning. It’s also critical to establish a strong connection between planning and execution (closed loop), including the ability to adjust planning data as needed, based on actual orders, consumed materials, or changes in production. This capability is more important than ever, with companies needing to realistically adapt planning and forecasting to a rapidly changing market environment.

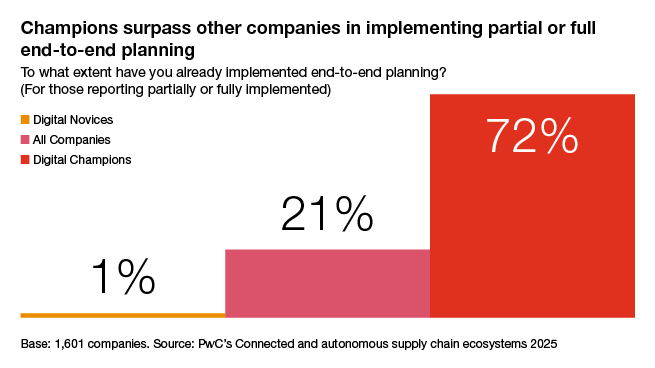

Planning that ticks all of these boxes is known as synchronised closed-loop planning. Most Digital Champions have already implemented end-to-end planning, one of the key components. And some have gone further and taken the required steps to continuously balance supply and demand, increase precision in execution and improve operational efficiency.

Smart logistics flows

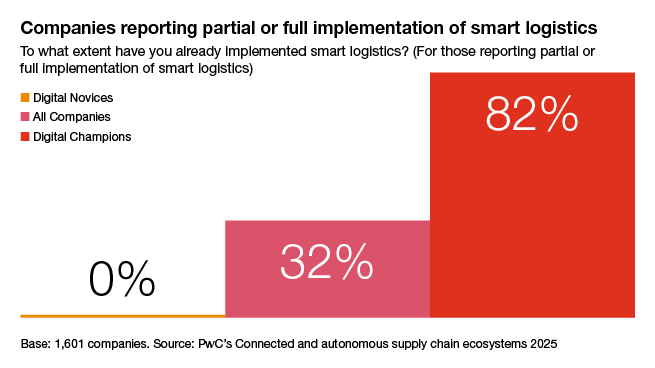

Managing and executing the physical flow of goods from the point of origin to the point of consumption is an essential part of the supply chain. Smart logistics — the next level of this coordination — connects the physical shipment and information flow between suppliers, manufacturers, distributors and customers interactively and in near-real-time, building on supply chain transparency and integrated planning.

Digital Champions rate smart logistics — including automated warehouses and next-level transportation management systems — as their top supply chain priority. Smart logistics accounts for more than half of overall supply chain cost savings, making it the key lever to maximise efficiency. It is also a key contributor to new revenue streams and resulting growth, as it is a key enabler for new business-to-business-to-consumer (B2B2C) and B2C business models.

By fully orchestrating all of the partners and processes in their logistics ecosystem, leading companies can turn their logistics network into a strategic asset that helps them better manage diverse channel requirements. It can also help them respond and adapt to potential shocks in the system, such as closed borders or shuttered factories in some countries.

Dynamic supply chain segmentation

Supply chain segmentation is the design and operation of distinctly different end-to-end supply chains from suppliers to customers and back. A whole range of potential attributes can define these segments, from the value of the individual customer, through product, manufacturing and supply capabilities, which then determine the configuration of the specific supply chain. It’s been an important lever for companies to save costs for at least a decade — but it's now entering a new era.

While in the past companies might have assigned each customer–product combination to a predefined segment, they are now moving beyond this practice towards a flexible, requirement-driven configuration of the supply chain where each transaction can be dynamically allocated to one of the supply chain segments. Key processes along the supply chain (plan, source, make, deliver) can then be tailored to best match specific business needs. Digital Champions in particular are making greater use of this enhanced, dynamic supply chain segmentation, which is based on smart algorithms that are applied on the individual product or transaction level. That helps them achieve greater customer centricity, flexibility and higher throughput, contributing to significant improvements in performance.

Dynamic segmentation also enables companies to continuously simulate and balance different tradeoffs when making decisions, such as costs versus service level, demand versus supply, product portfolio options (e.g., new product introductions and phase-outs) and supply chain flows by individual product. When all of these factors are considered, optimisation decisions can be taken based on a holistic total cost of ownership perspective.

AI driven supply chain management

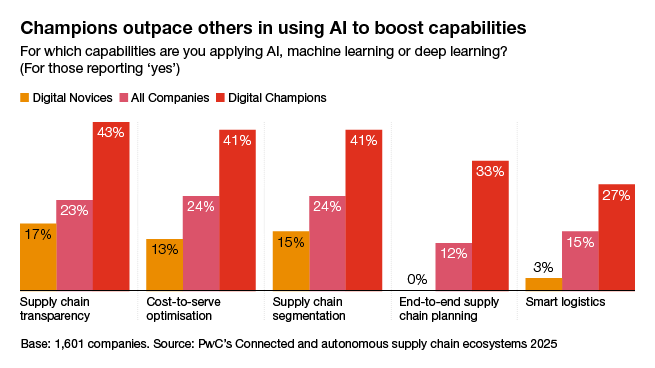

AI can be an enormously powerful accelerator of key supply chain capabilities, with the potential to drive efficient decision-making and build systems that can autonomously adapt to changing conditions. By applying sophisticated AI methods, such as machine learning and natural language processing, to supply chain capabilities, companies can increase transparency, improve planning and enhance logistics flows. Digital Champions are well ahead of the rest of the sample in this area; they’re making more extensive use of data and are more likely to be applying AI to turbocharge key supply chain decisions.

But leveraging AI isn’t always easy. Companies need to master the challenges posed by ensuring relevant data being generated throughout the supply chain. Intelligently combining structured and unstructured data provides the foundation for data analytics. Data points flow from diverse sources and may be generated internally, externally or from publicly available data sources. So establishing a data network that is able to read, clean and analyse all of these diverse sources is key. It’s also important to employ AI responsibly and with sufficient governance in place, for example by considering the interpretability and explainability of algorithms and taking possible biases into account, so that AI doesn’t become simply a ‘black box.’

Operating model development

For companies in our survey overall, the top three challenges are managing profitability, improving volume flexibility and increasing visibility and traceability. Digital Champions have already mastered these; they see circularity and sustainability, and technological maturity and reliability of master data as the key supply chain challenges. To master these, companies are using a few key strategies to drive advanced capabilities and encourage continuous innovation. Supply chain centres of excellence are a common starting point, and establishing a strong technology backbone is critical too, including state-of-the-art IT infrastructure. Digital Novices and Digital Followers are placing the most emphasis on the basics — integrating the IT function with supply chain to bring IT and business closer together — while for Digital Champions, embedding advanced analytics into supply chain functions is the top priority. That helps them establish an autonomous supply chain with the ability to be self-orchestrating.

With environments constantly changing, companies need to be able to continuously adapt and improve. That means focussing on people above all, for example, by upskilling the supply chain workforce or attracting digital talent and managing them in cross-functional teams. Ultimately, companies will need to encourage supply chain collaboration with external partners in a wider ecosystem to increase efficiency, speed up innovation in the supply chain and enhance organisational agility.

Contact us

Stefan Schrauf

Global Supply Chain and EMEA Operations Transformation Co-Leader, Partner, PwC Germany

Tel: +49-151-461-23326