Defining the new DNA of industrial digital organisations: the CEO’s agenda

November 19, 2019

Why digitisation is reshaping the manufacturing industry

Digitisation is revolutionising the way we work, the skillsets we need and the way we structure our organisations. Manufacturing organisations have begun to realise the role digitisation must play in improving their performance, with data, integration and problemsolving as the core drivers.

Already, digitally “smart” manufacturers are gaining a competitive advantage by exploiting emerging technologies and trends such as digital twinning, predictive maintenance, track and trace and modular design. These companies have dramatically improved their efficiency, productivity and customer experience by ensuring these capabilities are central to their operating models and by matching them with strong skillsets in analytics and IT.

How digitisation is changing the DNA of manufacturing organisations

Digitisation will have a sustained impact on operational and business processes as emerging digital technologies enable the creation of new processes, products and business models—and ultimately forge digital enterprises. For example:

- Manufacturing execution systems (MES) are enhancing automation, traceability and centralised control

- Digital twinning and simulators are facilitating more efficient and cheaper product development and creating models for new services

- Predictive maintenance and smart robots allow operations to monitor and manage their own health and order spare parts in good time

- Digital inventories and radio frequency identification (RFID) tags are improving production control, lead time analysis and capacity planning

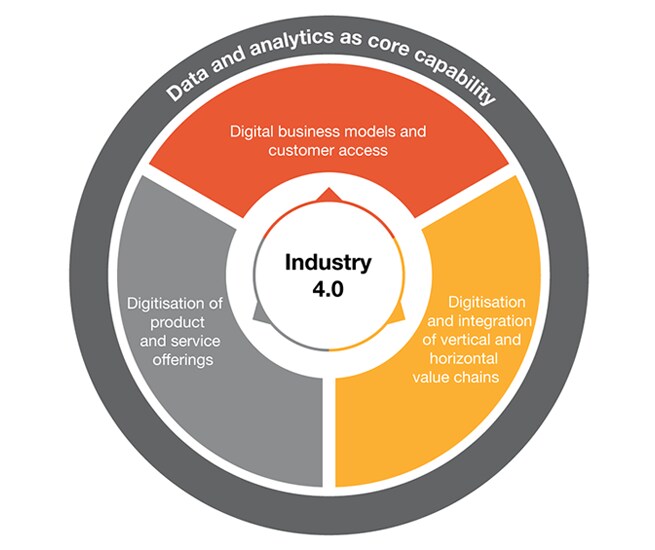

Digital enterprises consist of digitisation and integrated processes, products and business models

Source: Defining the new DNA of industrial digital organisations, part of PwC’s Global Digital Operations Study, 2018

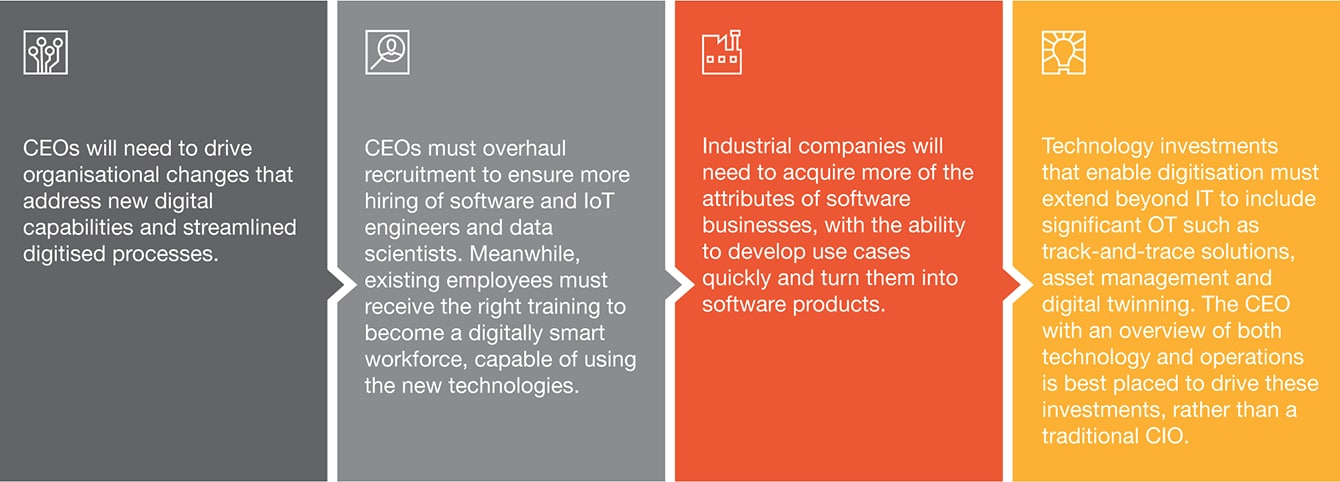

Successful digitisation – A four-point agenda for CEOs

Responding to the significant changes demanded by digitisation requires leadership and accountability from the top in four distinct areas.

On their own, none of these initiatives is sufficient to achieve the successful digitisation of a manufacturing organisation. Yet in combination they form an indispensable agenda for CEOs aiming to lead companies that are digital champions.