Making production at MINIT SLOVAKIA

Making production at MINIT SLOVAKIA, spol. s r.o. more efficient, with the ambition to become the most effective bakery firm in V4 A joint transformation project managed to increase production, improve planning, and involve people in implementing the change

Challenges for MINIT SLOVAKIA

Ambition to become the most effective firm in the V4 region

Lack of workforce in the region of Dunajská Streda

Year-on-year sales growth of more than 20% increases pressure and requirements on production and the entire company management setting

Preparation for a generational change in a family business

Ambition to become the most effective firm in the V4 region

A 9-month project involving key people at all management levels

Setting management tools for an effective management of company performance

“Company departments started co-operating much more intensively than ever before. A typical example is the collaboration between Sales and Production where even confrontational discussions from the past turned into common search for solutions.“

“In the past, we had to produce even 5 – 6 products on one machine a day. Thanks to sequencing, we now have all-day production for one product. This is also reflected in productivity.“

Benefit increase – labour productivity & throughput of production equipment

In M5, higher throughput was achieved by reducing the duration of redevelopments; efforts in improving labour productivity were mainly focused on centralizing replacers.

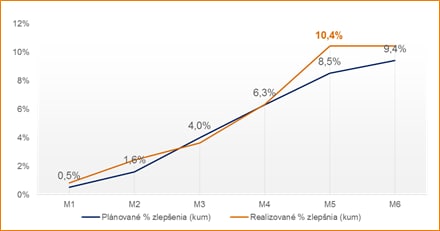

In M5, a throughput improvement of 4.1% (better by 1.8% than planned) was achieved, which is above project target.

Production throughput increase calculated via performed activities

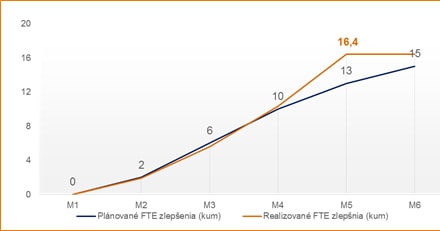

In M5, the project resulted in saving 6.1 FTE (16.4 FTE in total), which is better than the required level of 13 FTE.

Agreed optimization of FTE in production influences productivity

Contact us