Practical steps for responding to the coronavirus crisis

The coronavirus (COVID-19) outbreak is causing widespread concern and economic hardship for consumers, businesses and communities across the globe.

As the pandemic disrupts business as usual and throws the economic outlook into uncertainty, the automotive industry is on the front line. Some of the most affected regions are major production hubs and home to key links in the sector’s global supply chain. Typical contingency plans help enable operational effectiveness following events like natural disasters, cyber incidents and power outages, among others. They don’t generally take into account the widespread quarantines, extended school closures and travel restrictions that are being instituted in countries around the world to help stem the spread of the virus. With production shutdowns taking effect, automotive companies need to remain focused and nimble to better navigate this crisis.

The situation is fast moving with widespread effects. That’s why we’ve prepared this guidance which can help automotive companies to adapt the 'new normal'.

How Can We Navigate Through This Turbulence?

In order survive and strengthen themselves, automotive companies can have a phase wise plan in line with demand recovery, covering: strategic response, managing liquidity, workforce, supply chain and IT readiness.

How PwC can help

- In short term

- In the long term

In short term

- Review your workforce and travel

- Identify potential points of failure

- Evaluate the supply chain

- Revisit your crisis and continuity plans

- Use scenario analysis

- Get communication right

- Manage risks

In the long term

Strategy

- Create independent scalable business units with resiliency for future

- Leverage low valuation to acquire capabilities for future through M&A

- Identify low performing business and assets to sell for improved liquidity

- Develop new products considering new customers (tier-II & III), health, hygiene and connectivity needs

Front End:

- Shared mobility concerns can open up increased 2W, PV & used vehicle sales and pay-per-use model

- Concerns to visit showroom will lead to online! digital sales and marketing processes (manpower & OH savings)

- Network footprint and showroom sizes revaluated considering dealer viability

- Vehicles serviced and sanitized at door step to bring in hygiene transparency; reduced service center footprint

Supply Chain and Operations:

- Consider financial viability for future decide on ops restructuring, leadership and investments on hold

- Build digital thread across Ops. for faster decisions, lower human intervention, financial loss preemption, remote support

- Redesign supply base (on/off-shore, critical parts, alternative matl.) with real-time risk profiling (e.g. integrate blockchain)

- Reduced opex (e.g. lease, energy, supplies) considering optimized mfg. (lower prodn.) / office space (remote work)

Workforce:

- Restructure HR policies (e.g. health, remote working, travel, visitors, immigration, leaves, pay) through crisis learning

- Revisit labor union contracts (e.g. pay, leaves, benefits) for shared risk impact ownership for collaborative crisis mgmt

- Savings through shared services (legal, tax, finance, admin)

- Build scalable IT backbone for online and remote needs

- Convince need for multi-skilling and conduct relevant training programs

(e.g. coding)

We look at all components in the business, including the strategy, capabilities, cost and organisational structure and leveraging a standardised approach to support you in your journey to adapt to and thrive in the ‘new normal’.

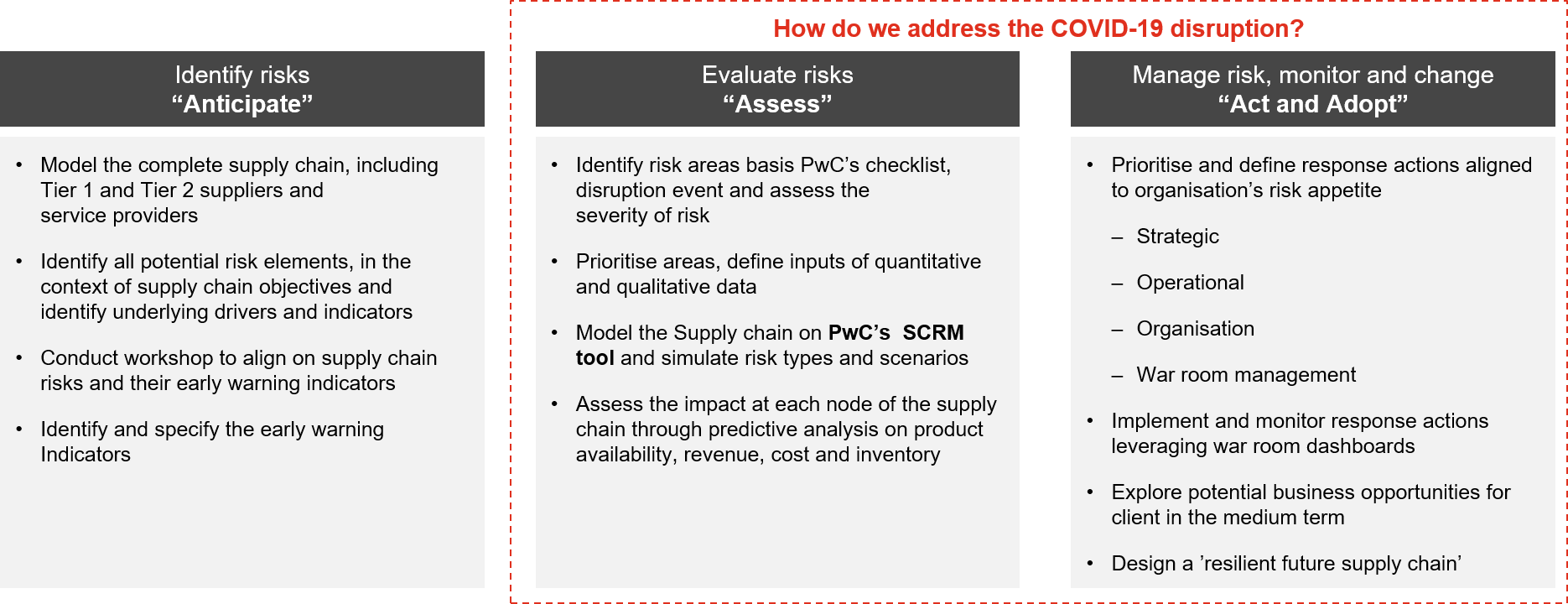

Our approach

Example of PwC’s standardised approach to enable companies to design a ‘resilient supply chain’

Get in touch

Sreenidhi Thubanakere

Director, Consulting Services, PricewaterhouseCoopers Consulting Vietnam

Tel: +84 28 3823 0796