Society is still in the midst of another industrial revolution. This progression, dubbed Industry 4.0, is using the power of the digital age and integration to transform every aspect of how manufacturing and other industries operate.

Artificial intelligence (AI) and machine learning are operational realities, helping companies improve the efficiency of their value chains and make better and faster decisions by having a deeper understanding of their customers. For example, AI-empowered analytics tools are making it easier for manufacturers to identify shifts in customer demand in order to adjust production lines while machine learning is helping companies enhance product quality, optimize inventory management processes and track products across a supply chain.

These innovations are only the beginning. Over the next few years, technologies will continue to mature, expanding to encompass more complex tasks and integrated processes. Canadian manufacturers are in a unique position to embrace digital transformation. Southwestern Ontario, in particular, is well positioned to lead advanced manufacturing and Industry 4.0 in Canada and globally, given it’s home to a number of industries—including automotive manufacturing—as well as leading academic institutions, start-ups and established companies developing digital tools and solutions.

Learning from digital champions

While Canadian manufacturers recognize the benefits associated with Industry 4.0, few have been able to make the transition to date. Although they may know why they want to change, they don’t really know how and are worried about the return on investment (ROI)

They aren’t alone. Globally, only 10% of companies in key sectorsOpens in a new window like auto manufacturing, consumer goods, electronics and industrial equipment, have been able to master the cultural, strategic and operational changes needed to support Industry 4.0. We call these organizations digital champions.

Digital champions have embraced Industry 4.0 and integrated it across their organizations—from their business strategy to operations to culture. For example, on the operations front, they typically have an end-to-end digital platform supported by the technologies like cloud-based software programs, AI analytics algorithms and IoT-enabled sensors, to manage their processes. This approach provides them with immediate insights into their customer needs, lets them make production changes faster and helps them manage inventory more efficiently. As a result, digital champions are more agile, responsive and operationally aligned, allowing employees to collaborate better.

A new lens for transformation

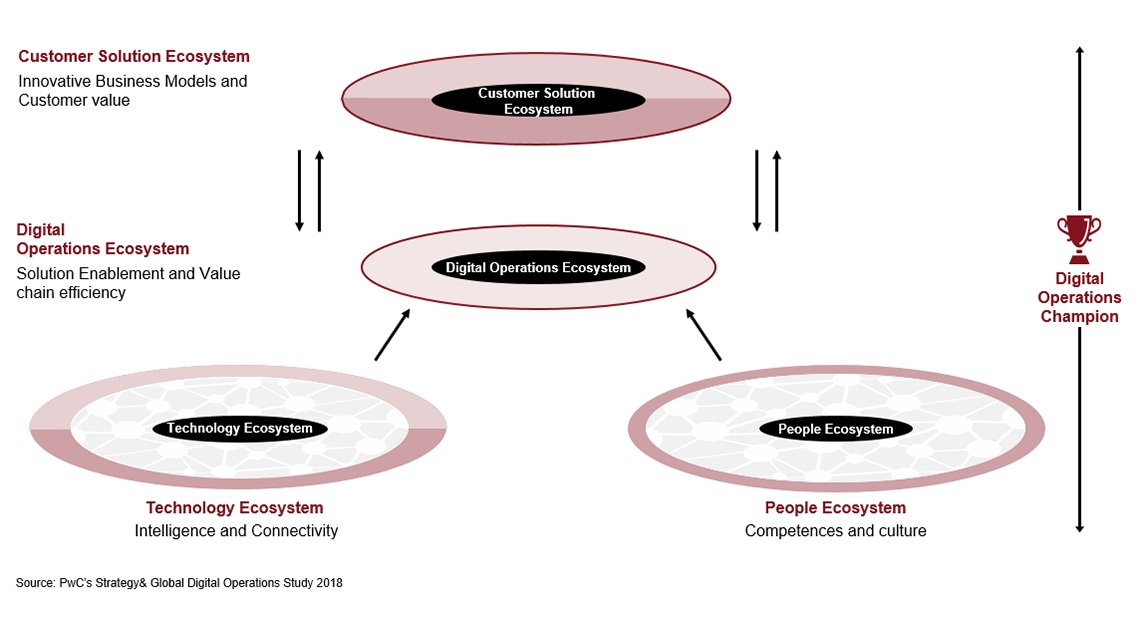

A digital champion shouldn’t look at their operations as separate functions but really as four interconnected ecosystems, with each contributing to the success of the whole.

This ecosystem includes customer-facing activities like products, quoting, services and customer service. In an Industry 4.0 world, digital solutions allow for the collection of customer insights and real-time information to support customer interactions, pricing and responding in a more coordinated manner.

For example, a company with a robust customer relationship management (CRM) system, supported by AI and analytics, can see the pattern of customer behaviours and the status of proposals around the world. Teams also have access to the same information real time—no more spreadsheets or lost information— allowing companies to can be proactive and spend more time on sales activities rather than being reactive.

The operations ecosystem is the backbone that lets manufacturers deliver more efficiently, whether it’s through procurement, manufacturing, logistics, order to cash or supply chain management. Sensors can provide production data and insights into plant efficiency, and operations can explore trends and identify anomalies using a dashboard.

Access to real-time data is one of the most critical aspects of an Industry 4.0 transformation. Companies that have centralized their operational data can then use it as a basis for making faster and more informed business decisions.

The technology ecosystem includes all technology underpinning an organization—from enterprise applications and CRM to cybersecurity solutions.

Digital champions use their business strategy to drive their technology choices, although they also keep an eye on technology advancements that could enhance their activities. There’s no difference between a company’s business and digital strategies. The technology component of their digital strategy helps power the company’s business strategy. It can’t operate in isolation.

What’s more, companies don’t need to do this all themselves. Having a partner or strategic alliance with other organizations can help them take advantage of digital opportunities and accelerating transformation.

People are the heart of any transformation. No matter what process, new technologies or tools an organization has implemented, if they aren’t embraced by your employees, the transformation will fail. The people ecosystem includes workforce activities like training, upskilling, performance management, recruitment and workplace design.

Digital champions recognize that Industry 4.0 integration depends on people having the right tools, training and skills needed to embrace changes to the work they do and on the flexibility mobile connectivity and access to the cloud provides. That’s why more than 90% of global high-digital- IQ organizationsOpens in a new window have someone in charge of the employee experience. When people across ecosystems buy into changes, the entire company will benefit.

Starting the Industry 4.0 journey

Thinking about Industry 4.0 and its impact across these four ecosystems can be overwhelming. Many CEOs tell us that they’re experimenting with Industry 4.0 but are concerned about managing existing priorities, costs and the distractions of starting the journey.

Your first step is to take a methodical approach to Industry 4.0 and make sure your digital strategy supports and is aligned with your business strategy. Consider the following five steps:

- 1. Identify a digital strategy champion

- 2. Upskill your team

- 3. Create a plan that builds momentum

- 4. Develop an integrated operations model

- 5. Take advantage of the new value chain

1. Identify a digital strategy champion

Identify a person like a chief digital officer— and eventually a team—to champion the change, lead strategic initiatives and articulate how the digital strategy will support the business strategy. This isn’t about IT or new technologies; it’s about how processes, experiences, people and capabilities will be transformed using digital. This person should be a senior leader and have credibility with buy-in from the CEO and leadership team.

2. Upskill your team

Upskill your team: It all starts with your people, giving them the skills and knowledge to understand digital and how to apply it in their jobs. The first step is to evaluate your current state across each ecosystem to identify gaps and opportunities for improvement. Envision a future state for each ecosystem based on new, interconnected capabilities.

3. Create a plan that builds momentum

Determine what problems you’re going to focus on. Define what investments you need, when you need them and what’s realistic. Develop an agile approach for prototyping and launching solutions early and often, driving benefits early and course correcting as needed. In this fast-changing environment, waiting or taking too long isn’t an option.

4. Develop an integrated operations model

Design an integrated operating model that spans all four ecosystems. It’s also important to consider external partnerships where you can benefit from other initiatives like cloud-based programs that may be complementary to the various ecosystems.

5. Take advantage of the new value chain

After your four ecosystems are developed, make sure you have the structures in place to get the most value from Industry 4.0 integration. Verify that you’re getting the benefits, as your digital champion should be monitoring activities, measuring results and making continuous improvements.

Contact us